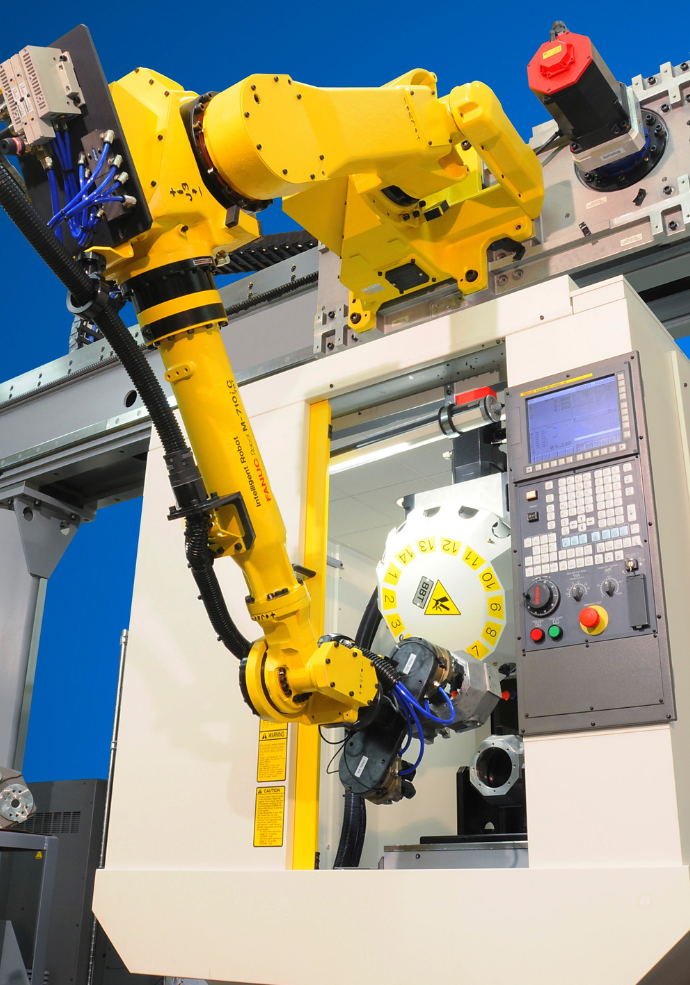

In the midst of modern manufacturing, robot arms are challenging the norms of production, mixing safety, precision, and efficiency in ways previously unimaginable. The mechanical marvels, often called robot arms become essential to industries across the globe, due to the urgent need to cut costs without sacrificing quality. Through the integration of robotic arms into production lines, manufacturers have not only reduced costs but also transforming workplace safety and efficiency. Find out how these robotics have changed the industrial landscape.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Factory owners are under constant pressure to reduce accidents at work, reduce manufacturing errors, and decrease the amount of waste. Robotic arms face these challenges head on. Robot arms eliminate costly mistakes and help reduce the waste of raw materials by performing repetitive tasks much more precisely than human beings. For instance, in large-scale industries such as automotive manufacturing arms ensure precise welding and part placement, ensuring flawless assembly every time. This accuracy translates into substantial savings, since less defective products means less work and waste.

Safety is another important aspect of the robot arm revolution. Many manufacturing tasks such as handling hazardous materials, or operating machines that are heavy pose a risk to human workers. Robot arms enable companies to eliminate their workers from hazardous surroundings and decrease injuries in the workplace. Robotic arms, made up of joints which move can replicate the functions of human arms without causing physical harm. These machines are equipped with robotic hands or end-effectors that can be programmed. They are capable of performing tasks like grasping, spinning and welding, in conditions that could make it dangerous for humans.

The range of applications for robot arms is a game changer for many industries. From assembly for automobiles to electronic production, robotic arms are able to adapt to a wide range of jobs. They are able to perform complicated tasks with unparalleled precision, such as painting and tending with a machine. Robotic arms for warehousing have revolutionized palletizing through the automation of loading of pallets with goods. Automation not only increases effectiveness but also guarantees reliability, as robot arms can work continuously without fatigue.

Cobots are a new breed of robots that operate together with humans. Cobots with robotic arms, in contrast to traditional industrial robots, which are housed in separate cells, are specifically designed to interact with human beings safely and seamlessly. Cobots with robotic arms can perform difficult or repetitive lifting tasks in a factory which allows human workers to concentrate on more complex duties. The collaboration improves productivity and creates a safer work environment, as cobots can be programmed so that they can adjust or stop their movements when the person in front of them is.

Robotic arms have a significant impact on modern manufacturing, and not just in terms of safety, but also efficiency. Their ability to perform tasks like welding or assembly, as well as material handling with high accuracy has made them essential in high-risk industries. Robot arms, for instance, can be utilized to move and rotate parts during assembly in the automotive industry to ensure that they are perfectly aligned with no human involvement. Similar to electronics, robot arms handle delicate components with care, minimising damages and improving the quality of output.

Robotic arms will become more important as industries grow. Their capacity to cut costs, improve safety, and adjust to different tasks make them a cornerstone of manufacturing’s future. Robot arms that blend cutting-edge technology and human creativity, are not only tools as much as they are partners in progress. They are the engine behind technological innovation and alter the way that the world is built.